Mastering DTF Printing: Tips and Techniques for Getting Vibrant and Resilient Prints

In the world of textile printing, accomplishing lively and sturdy prints is a sought after skill that can elevate the top quality of your result. From picking the appropriate products to make improvements print setups and developing post-printing ending up strategies, there are numerous factors that can influence the end result of your prints.

DTF Printing Basics

For those new to the world of textile printing, recognizing the basics of DTF printing is vital to grasping this innovative strategy. Straight to Film (DTF) printing is a modern approach that includes transferring layouts from a special film onto numerous textiles using a warmth press. Unlike standard methods like display printing, DTF uses advantages such as vivid colors, detailed describing, and the capability to print on varied materials like cotton, polyester, and blends.

The procedure begins by publishing the design on an unique DTF film using a suitable printer with CMYK or CMYKW ink sets. As soon as the style is published, it is then healed with a heat press to develop a sturdy and resilient print. DTF printing is known for its capability to reproduce complicated layouts with high precision and shade accuracy, making it a preferred choice for organizations wanting to develop custom clothing, advertising products, and much more.

Selecting the Right Materials

The glue powder acts as a bonding agent in between the published design and the textile, so it needs to have strong attachment homes to guarantee a resilient and resilient transfer. By meticulously selecting the right products for DTF printing, printers can enhance the top quality, vibrancy, and durability of their prints.

Optimizing Publish Settings

When intending to achieve the very best lead to DTF printing, thorough attention to maximizing print settings is vital for making certain premium and specific transfers onto textiles. One crucial element to consider when maximizing print settings is the resolution. Higher resolutions usually cause sharper and more comprehensive prints, enhancing the total top quality of the transfer. Furthermore, readjusting the ink density can aid make sure and attain vibrant colors that the style attracts attention on the fabric.

An additional essential setup to maximize is the print rate. Locating the appropriate equilibrium in between rate and high quality is crucial. While boosting the rate can enhance effectiveness, it may Bonuses compromise the final print's quality and shade saturation. Try out various rates and observing the outcomes can assist identify the optimal setting for each and every print work - DTF Printing.

Moreover, adjust color accounts and making certain appropriate color monitoring are essential for attaining regular and precise colors throughout different prints. By adjusting shade settings and accounts, printers can lessen color inconsistencies and create uniform outcomes, enhancing the total print high quality and customer satisfaction.

Preparing Art Work for DTF Printing

Transform the art work to CMYK shade mode to guarantee that the colors equate precisely from display to print. Bear in mind to mirror the last design before printing to guarantee that it transfers properly onto the garment. By complying with these steps and paying close interest to the information, you can prepare artwork that is enhanced for durable and vibrant DTF prints.

Post-Printing Finishing Techniques

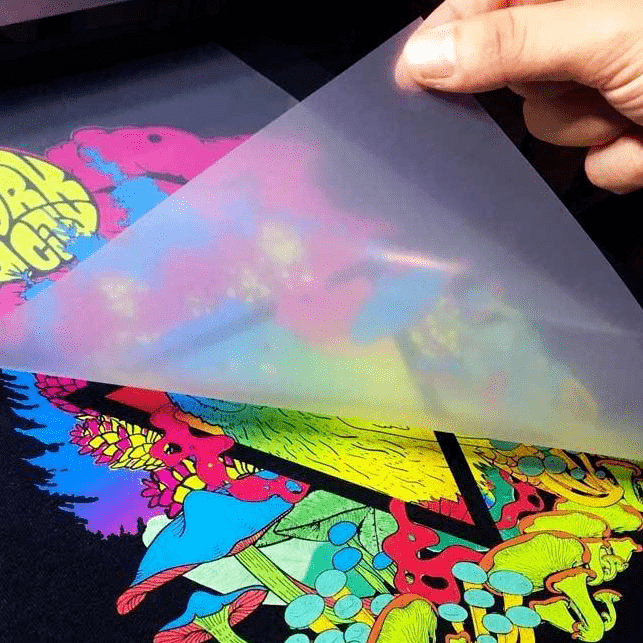

Executing effective post-printing ending up strategies is vital to improving the resilience and aesthetic charm of DTF prints on textiles. As soon as the printing procedure is total, applying warmth to the printed layout is necessary.

As soon as the film is eliminated, the print may need added treating time to better set the ink right into the textile. This step assists boost the washability and sturdiness of the print, guaranteeing it can endure numerous wash cycles without fading or fracturing.

Additionally, cutting any kind of excess film around the style can offer the last print a expert and tidy appearance. Taking the time to appropriately end up DTF prints post-printing can significantly affect the general top quality and longevity of the fabric layout.

Verdict

Finally, grasping DTF printing calls for a thorough understanding of the basics, choosing ideal materials, optimizing print settings, preparing artwork efficiently, and using post-printing ending up strategies. By adhering to these tricks and suggestions, one can accomplish lively and long lasting prints that fulfill their wanted high quality requirements. Constant technique and focus to information are necessary in attaining effective results in DTF printing.

From choosing the his response best materials to fine-tuning print settings and perfecting post-printing ending up strategies, there are many aspects that can influence the outcome of your prints. Unlike traditional approaches like display printing, DTF uses advantages such as vibrant colors, intricate describing, and the capability to print on varied materials like cotton, polyester, and blends.

Once the layout is published, it is then cured with a warmth press to produce a long lasting and lasting print.When intending to achieve the ideal results in DTF printing, meticulous focus to enhancing redirected here print settings is crucial for making certain top quality and specific transfers onto textiles.In conclusion, grasping DTF printing requires a detailed understanding of the fundamentals, selecting ideal materials, maximizing print settings, preparing art work efficiently, and making use of post-printing finishing strategies.